Cut margin

The box is made out of some material, and the sides of the boxes fit into eachother by means of the notches.These notches should fit nicely into each other.

From normal wood working we know that one should take the saw thickness into account. That can easily be done by sawing

on a side of the drawn line instead of sawing in the middle. With a laser cutter this cannot be done. The laser cutter follows

exactly the line it should follow.

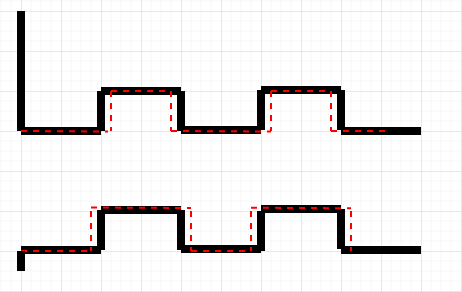

The laser cutter will remove material of half the laser beam width at the left side and right side of the drawn line.

The result is that the notches fit too easily.

You can compensate for this effect by using the 'Cut Margin' setting. You need to know the diameter of the laser beam. If that is not known then you could draw a square of a certain size, cut it, and measure the width. The measured widht is smaller than the drawn width, on both sides half the laser diameter is missing. Thus the difference between your drawn size and the measured size is the diameter of the laser.

Field: 'Cut margin':

Value should be entered in millimeter [mm] resolution.

Fractions are allowed, 0.08 is a correct value.

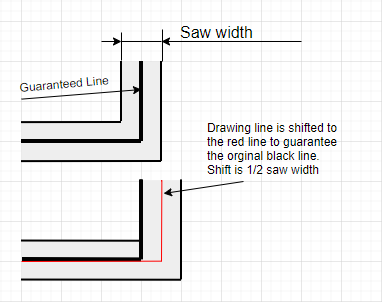

Next drawings further clarify if above text was not clear:

Assume we want to make sure all material left of the 'Guaranteed Line' remains.

That means we must shift that line with half of the saw width to the right.

For the notches the black line is the original drawing. The red line is the result of applying a non zero Cut Margin value.